Arsenal

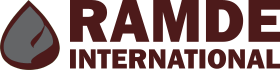

Arsenal is a rapidly growing independent provider of coating solutions and drilling tools, particularly the ultra-low friction engineered polymer centralizer Slip ‘N Slide and the Phantom glass-coated float sub.

Products

Contact Info

- PO BOX 79822 HOUSTON TX 77279

-

Phone : 713.609.9802

Phone : 281.734.8989

- Andres Ramirez andy@ramde.net

- Maryann Phillips sales@ramde.net

- Gaby Carrera & Amando L Ramirez accounting@ramde.net

- Mon - Fri 08:00 - 17:00

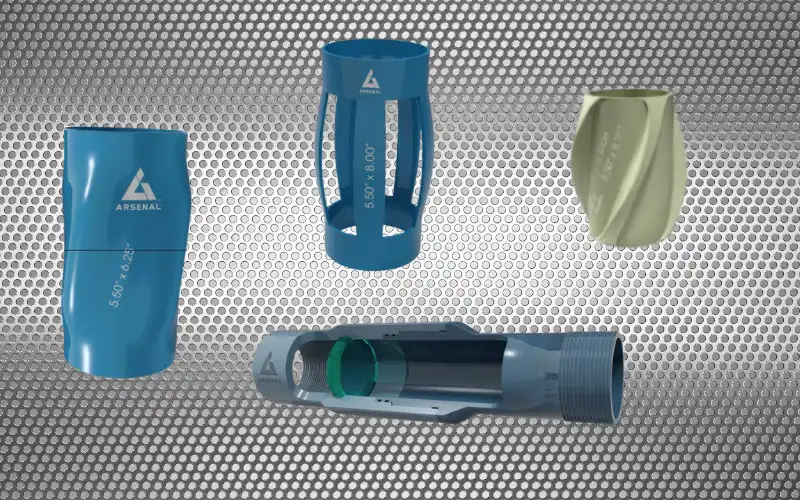

Centralizers

The low-friction engineering polymer centralizer from Arsenal (Slip "N Slide’M) is used during casing operations and cementing operations. Slip N Slide ensures that the casing strings efficiently reach total depth, provides optimal separation for mud displacement, and enhances cementing operations. Slip “N Slide’M is the ultimate in downhole centralization and offers proven lower friction coefficients in the field, leading to superior strength and reduced rotational torque. The tool is made from a high-temperature, high-pressure injection molded proprietary engineering polymer composite.

Features

- Unparalleled torque and drag reduction.

- Can allow the casing to slide to the bottom without rotation.

- Can eliminate the need for additional friction reduction tools.

- Provides support while drilling with casings or liners to ensure reaching target depth.

- Helps extend current well construction limits in extended reach drilling and highly deviated wells.

Advanced Elastomers

One-piece centralizer type. Weight (pounds) 12.12. Application centralization. Arc material EN 42J. Iron phosphate coating 8. Powder-coated neck material EN 42J.

Features

- Number of bows 5.

- Standard according to API 10D.

- Type of straight bow.

- Initial force (pounds) [o].

- Bow width 1.500".

- Stroke force (lbs) o

- Bow thickness 0.158".

- Restoring force 2,653

Floaters

The disappearing glass flotation submarine is easy to operate and does not require on-site personnel. The sub-patented flotation pump opening device is configured to open at a specific differential pressure. Simply increase the pressure to a preset value and the sub opens. Arsenal delivers the flotation submarine in standard and custom hole diameters. Higher pressure and temperature ratings can be assessed upon request.

Features

No waste trap or landing collar needed.

High debris tolerance.

Full access:

- Activation pressure specified by the customer

- No personnel required.

- No impact on cementing operation or downhole equipment.

- Reduce casing running time

- No special cement plugs needed

- Shorter shoe track, more pay zone

Casing rotation:

- Packer setting

- Pressure testing

- Fluid loss control device

- Multiple casing sizes

- Sliding sleeve floatation

- Completion systems

- Liner floatation

Airformed Centralizer

CASINGSIZE 5.500″ ID 5.620″ OD 6.250″ LENGTH 8.500” PART NUMBER AF1-05500-06250

Features

- Type: without laces

- Material: Carbon steel (U.S.)

- Manufacturing process: Seamless pipe forming

- Number of blades: 4

- Blade type: spiral